Solution Background

With the continuous prosperity of the electronic market, the replacement of electronic products such as smartphones, tablets, refrigerators, washing machines, desktop computers and televisions is also accelerating. Electronic waste usually contains a large number of toxic substances such as lead, chromium and mercury, which cause great pollution and wide harm. If not handled properly, it will not only cause waste of resources, but also bring great environmental pollution, and even directly threaten human health.

At the same time, e-waste is rich in gold, silver, copper and other precious metals, and its economic value is comparable to that of "mines". After professional recycling, copper, aluminum, plastics, rare and precious metals and other renewable resources can be sorted out through professional disposal such as "crushing disassembly sorting", which has great economic value.

Solution Introduction

System Introduction

Brand:ZHIHAO

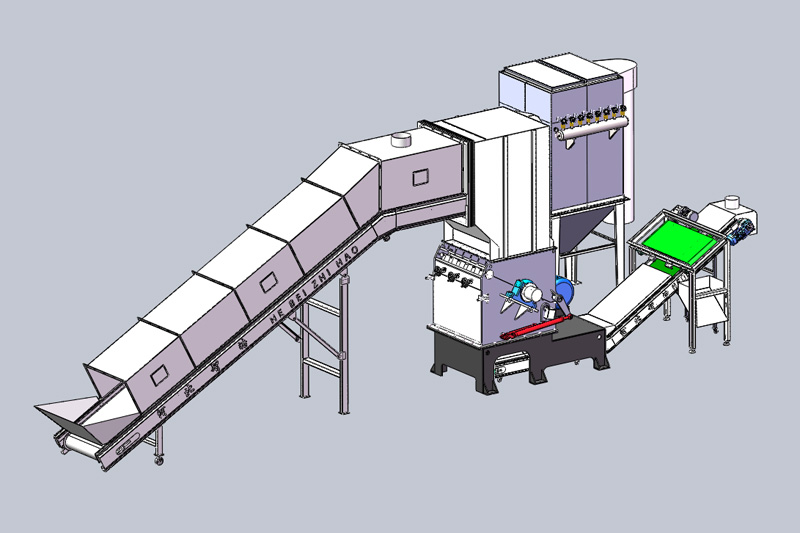

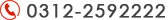

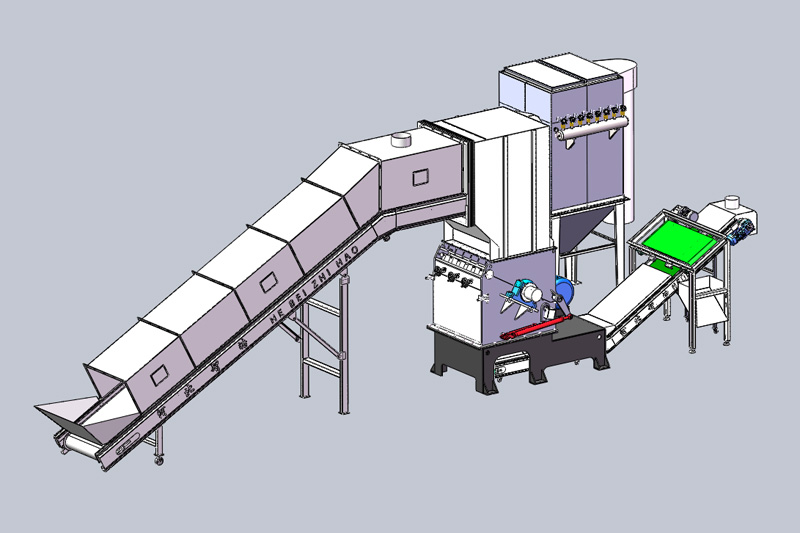

Brief introduction:Waste washing machines are recyclable waste. In the context of recycling and recycling of renewable resources, we have produced a complete set of waste washing machine disassembly and crushing production lines. It can quickly and effectively recycle the available resources in the waste washing machine. The dismantling platform of waste washing machines adopts new dismantling technology to realize the dismantling and reuse of waste washing machines; There is no waste gas and waste water during disassembly, and no dust leakage, which meets the national environmental protection requirements.

Applicable Materials

Waste washing machine

Disposal Solution

Main Equipments

Performance Advantage

-

All electrical components of the supporting equipment are imported brands such as Mitsubishi / NSK / Schneider, France, and the matching cables are domestic first-line brands, which meet the national mandatory standards. The iron recovery rate of the production line is ≥ 99.5%, and the plastic separation rate is ≥ 98%.

-

The whole production line adopts Mitsubishi PLC automatic control, has CCTV monitoring system and big data center, can collect operation data of all equipment, has operation fault alarm function, better analyzes the operation data of the production line for the owner, calculates the operation cost, and optimizes the operation rhythm.

-

The feeding and conveying of the crusher adopts a closed device to prevent material leakage, and the soft connection seal is used with the feeding inlet of the crusher, which has a better sealing effect and can prevent materials from flying out during the crushing time and avoid personal injury; Equipped with automatic feeding and discharging device to realize automatic production and ensure production efficiency and personnel safety.

-

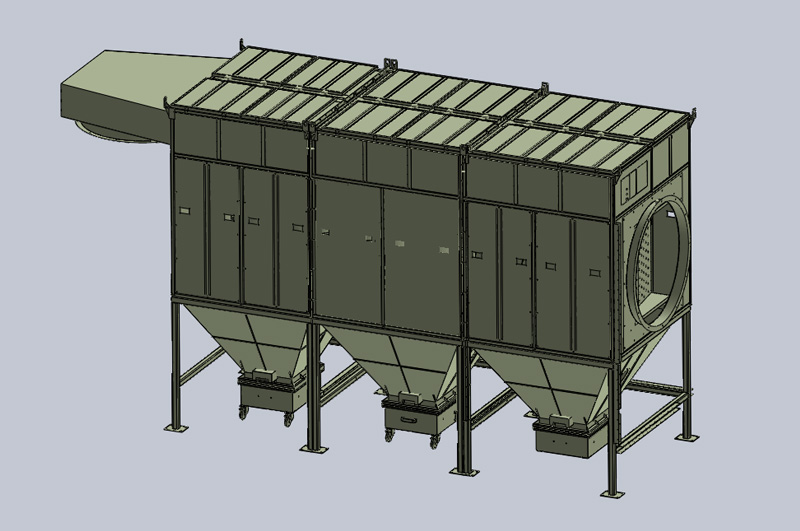

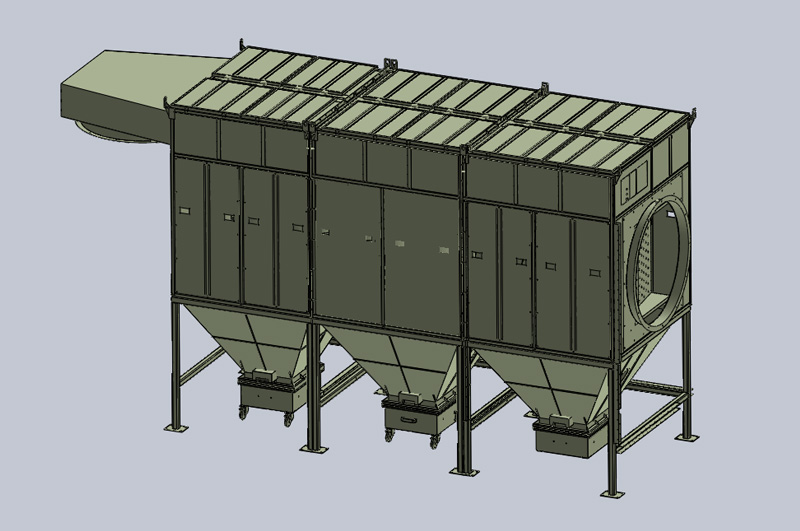

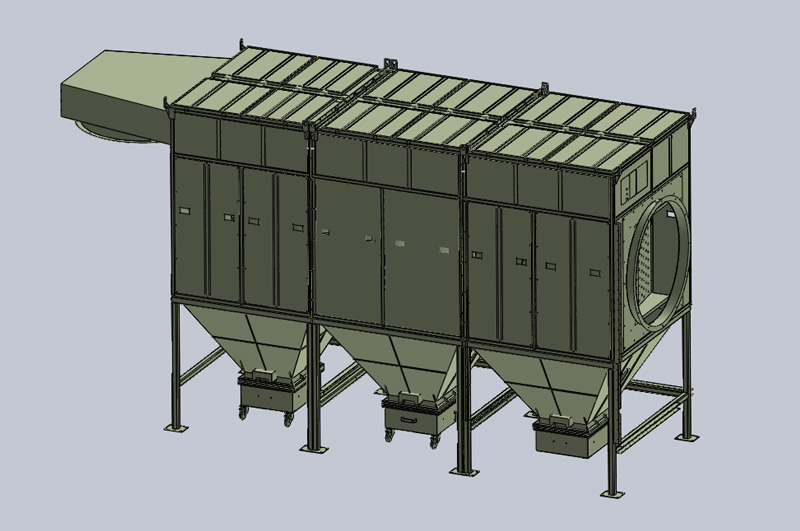

The compact and reasonable layout and sealing structure of the whole production line, coupled with the design of negative pressure dust removal, can fully and effectively suppress dust leakage and achieve dust-free work; The filter cartridge pulse dust removal can effectively solve the dust problem and meet the requirements of environmental protection.

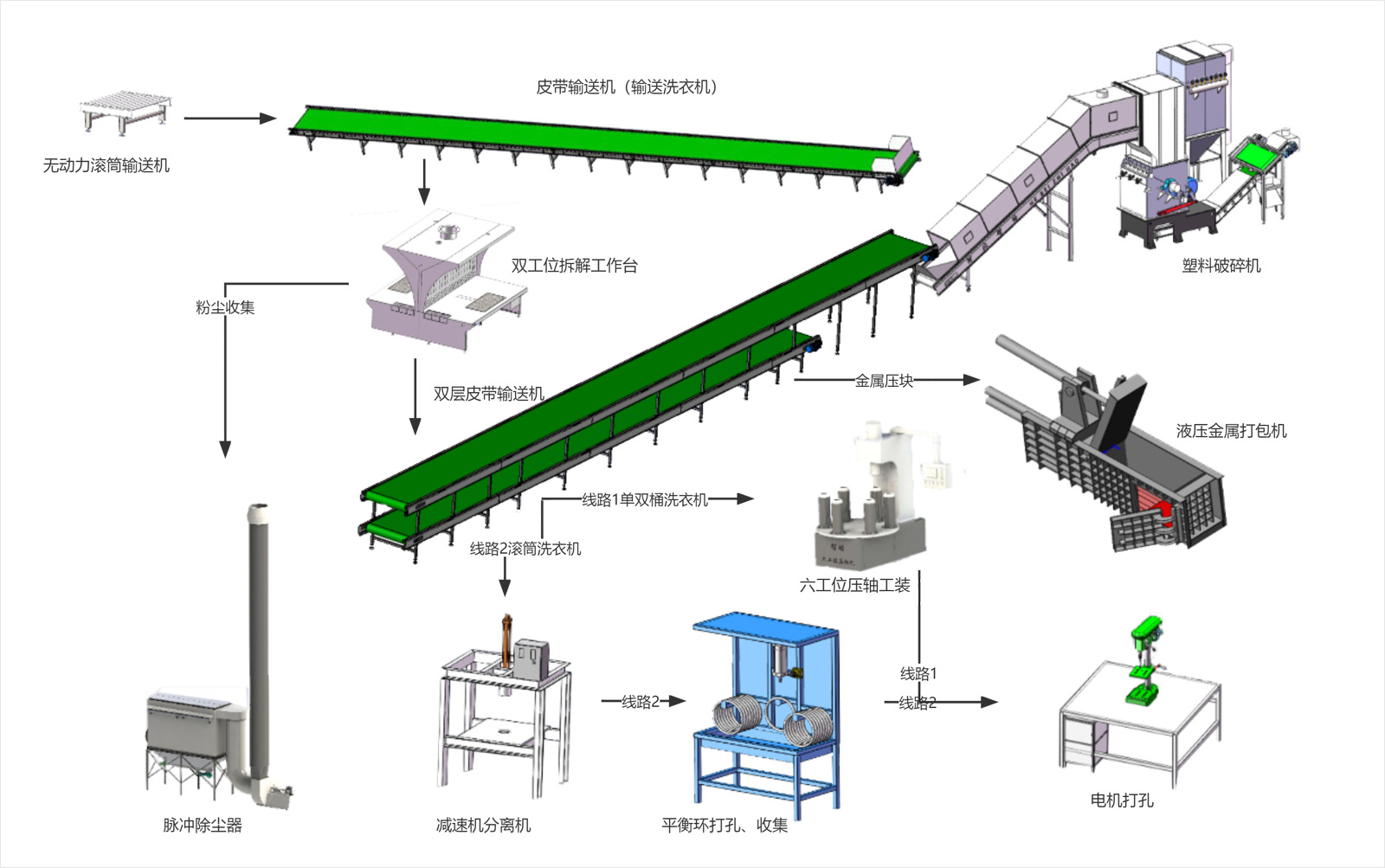

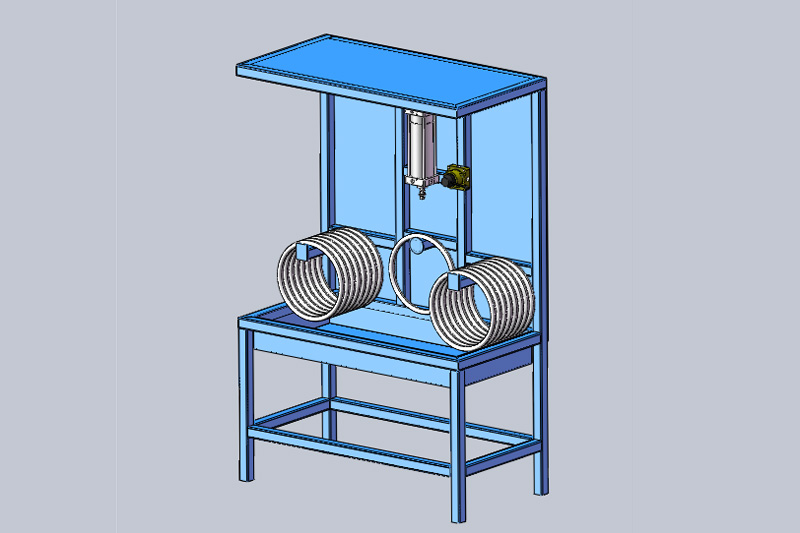

Shaft pressing system

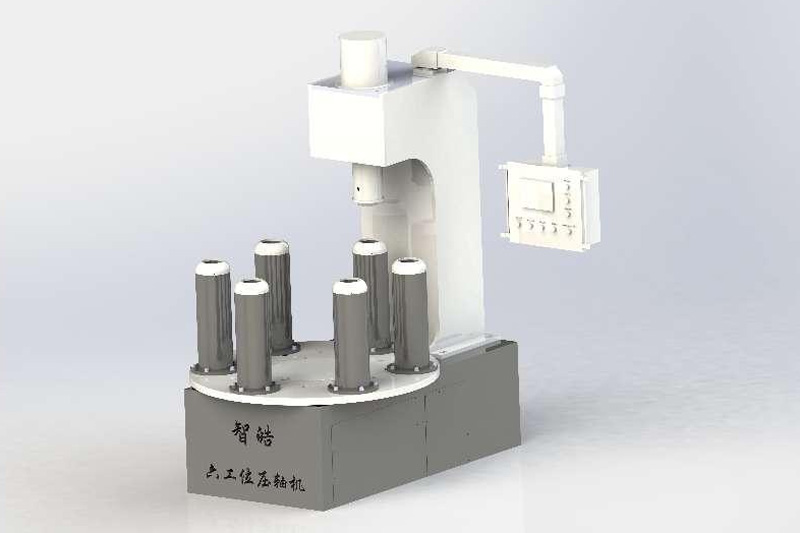

Shaft pressing system  Punch System

Punch System  Punch System

Punch System  Crushing system

Crushing system  Dust removal system

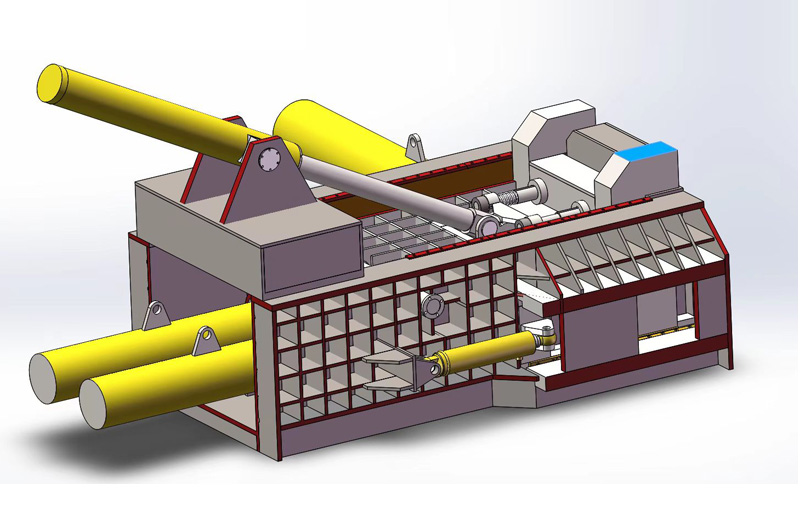

Dust removal system  Packaging system

Packaging system